The Illusion of Control

For years, USB temperature loggers — often called “PIMs” (Plug-In Modules) — have been the industry’s go-to solution for monitoring temperature sensitive shipments. They are simple, inexpensive, and easy to drop into a load. In an era where food safety regulations are tightening and transportation costs are soaring, relying on after the fact data has become a dangerous gamble. When it comes to protecting perishable goods during transit, timing is everything.

The Cost of Delayed Information

Consider a common scenario:

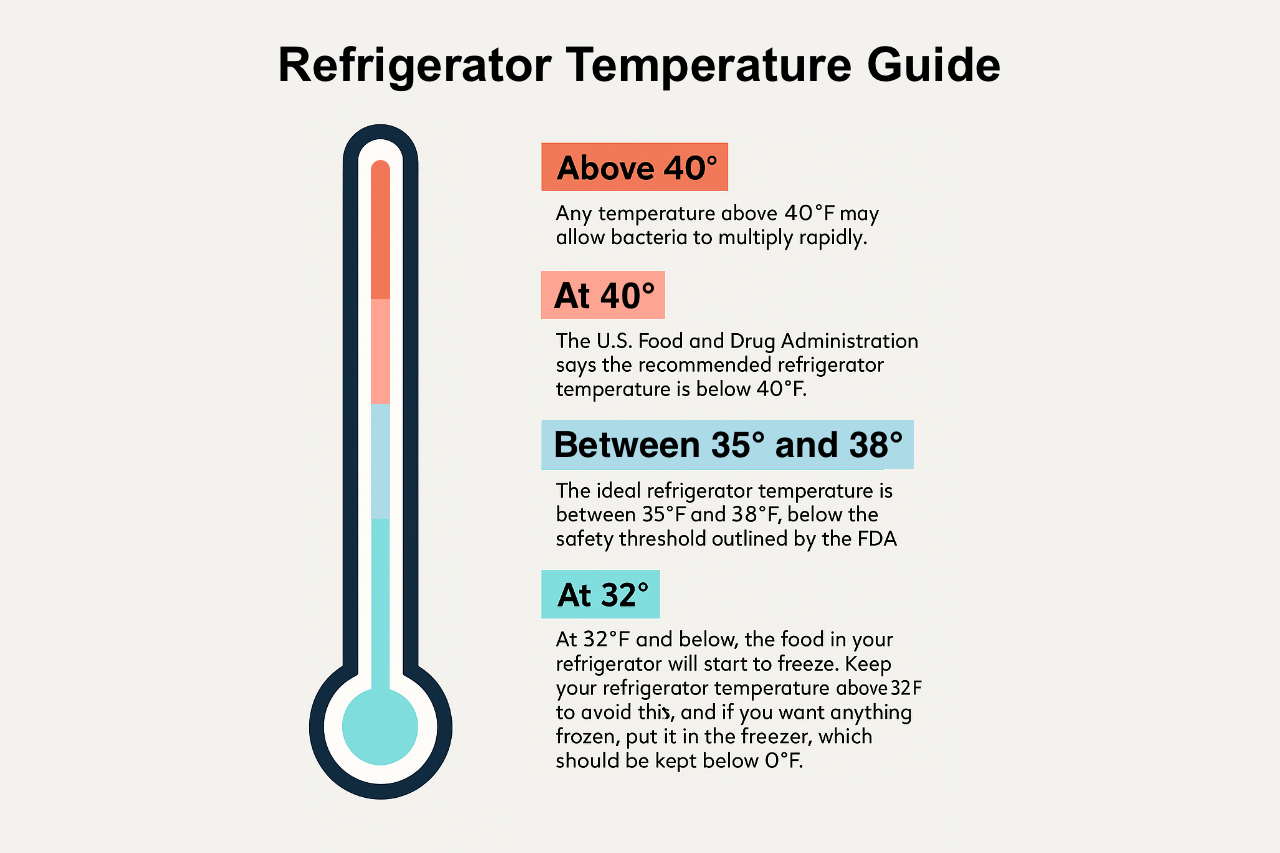

A refrigerated trailer loaded with sensitive produce leaves a packing facility and begins its long journey. Midway through transit, seven hours from its destination but only 90 minutes from a nearby distribution hub, the refrigeration unit fails. The temperature inside the trailer begins to rise.

- With a USB data logger:

The problem remains invisible until the truck arrives seven hours later. By then, the cargo may be compromised, and fuel, driver time, and labor have all been wasted. Even if partial salvage is possible, the damage is done. The loss extends beyond the cargo, affecting customer trust, compliance records, and operational efficiency. - With Capti’s real-time monitoring system:

The rising temperature triggers an immediate alert. Dispatch sees the deviation while the truck is still within reach of the distribution hub. Instead of completing the full trip with compromised product, the load can be rerouted, partially salvaged, or proactively serviced. The financial and operational savings are immediate.

The Labor Burden of USB Loggers

USB loggers aren’t just late — they are labor-intensive. After arrival:

- Each logger must be retrieved manually.

- Data must be downloaded, processed, and archived.

- Human error can lead to missing, incomplete, or inaccurate records.

- The entire process delays corrective action for future shipments.

In contrast, Capti’s platform:

- Streams data automatically into your system.

- Centralizes temperature records across your entire fleet.

- Enables instant reporting for compliance audits.

- Eliminates manual handling entirely.

The Hidden Costs of Old Technology

While USB data loggers may seem affordable upfront, their hidden costs add up:

- Lost loads from undetected failures.

- Wasted fuel, labor, and driver time.

- Compliance risks from missing or corrupted records.

- Delayed corrective action.

- Reduced customer confidence after a failed delivery.

Real-Time Visibility is the Future of Cold Chain

In cold chain transportation, you don’t need to know after something went wrong. You need to know while it’s happening. With Capti’s real-time cold chain monitoring:

- Intervene instantly: Save product and costs by rerouting or servicing en route.

- Streamline compliance: No more chasing devices or manually downloading logs.

- Protect customer trust: Deliver consistently safe, high quality product.

The cold chain has evolved. Do not let your technology hold you back.

USB data loggers? They are already too late.

Keep It Cool with Capti™

With Capti’s cold chain monitoring solution, you gain true real-time visibility into every shipment. Whether you are managing a single delivery or an entire distribution fleet, Capti ensures you never miss a critical temperature deviation. Stay informed. Stay compliant. And most importantly keep it cool.

Ready to safeguard your cold chain in transit?

Explore Capti’s solutions and take control of your shipments before problems arrive at the dock.